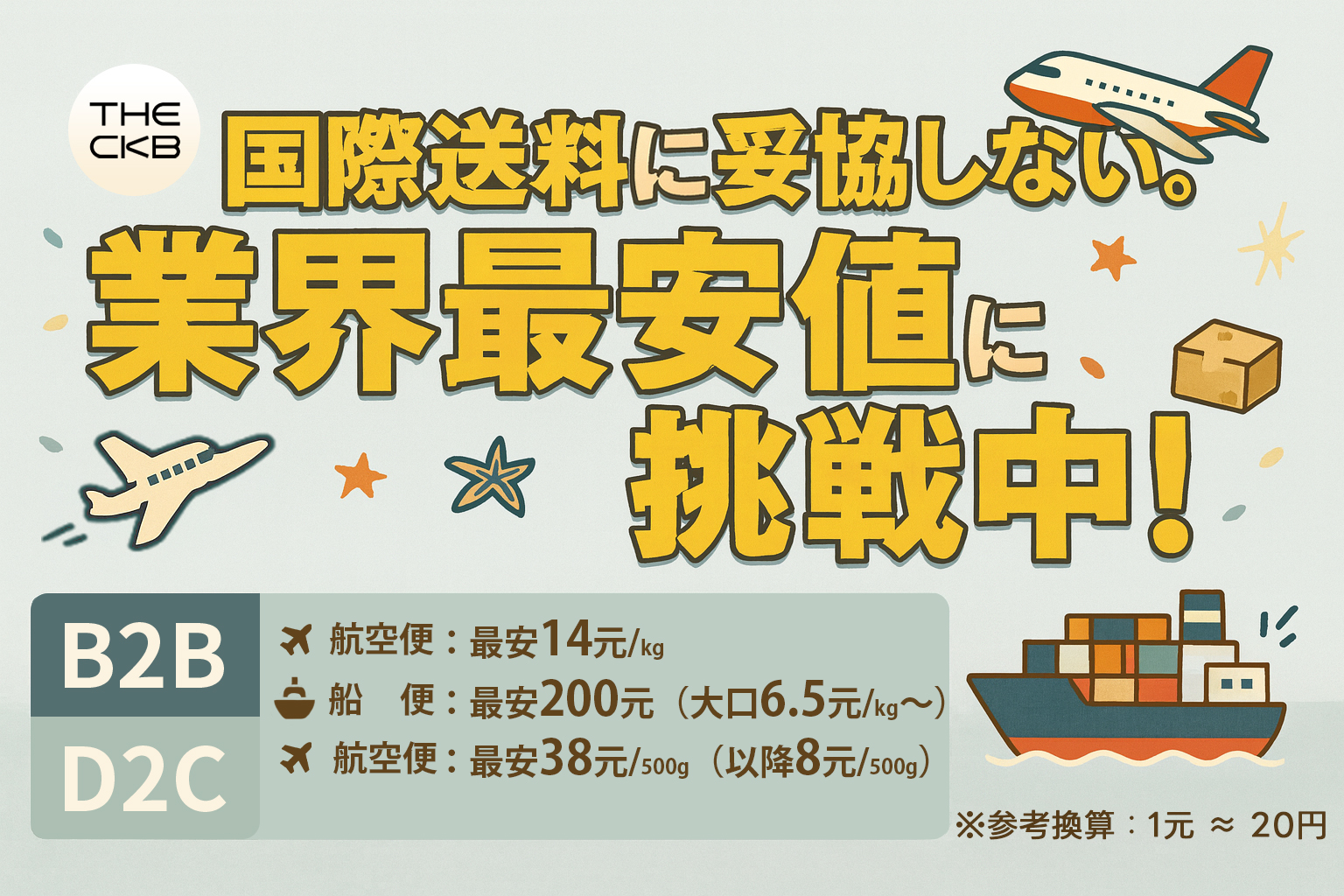

コストに妥協しない。最安水準の国際送料、ここに。

\ 他社より高ければ、ぜひ教えてください! /

小口直送も大口発送も、国際送料は業界最安水準。

無料登録ですぐに送料をシミュレーション。

自社商品のコストを事前に把握できるから、初めての海外仕入れでも安心です。

▶︎詳しくはこちら:https://www.theckb.com/price/shipping-fee/

🗓 期間限定!10月17日(金)~10月31日(金)

今ならさらにお得!新規登録で「送料無料クーポン」プレゼント!🎁

通常も最安水準の国際送料が、今だけ無料に。ぜひお見逃しなく!